Commonly used refractory bricks in hot blast stoves mainly include silica bricks, high alumina bricks, clay bricks, mullite bricks, etc. Each type of hot air stove may be different depending on the use. Refractory fire bricks for hot blast stoves. The selection of refractory materials for hot blast stoves is mainly determined by the hot air temperature of the hot blast stove.

High Alumina Bricks for Hot Blast Furnaces

Generally, when the wind temperature is less than 900°C, clay bricks are often used. When the air temperature is between 900 and 1100°C, high-alumina bricks, mullite bricks, or sillimanite bricks are used for the furnace lining, and checker bricks in the high-temperature part. When the air temperature is higher than 1100°C, high alumina bricks, mullite bricks, and silica bricks are generally used as furnace lining or checker bricks. But the overall difference is not bad. Today we focus on high alumina bricks for hot blast stoves.

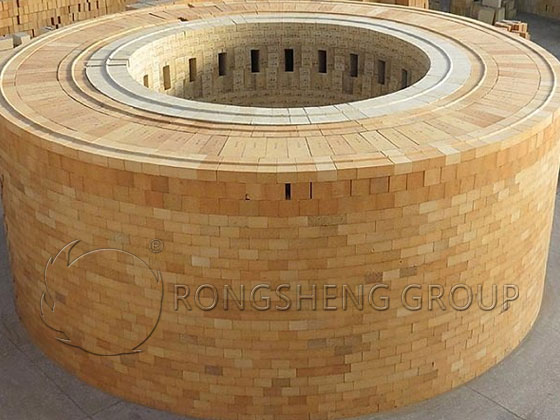

High alumina bricks in hot blast stoves are often used in checkered bricks on the upper part of hot blast stoves, rotating bricks on vaults, and large walls, that is, they are used in high-temperature parts of hot blast stoves. The high alumina bricks produced by RS Cheap Fire Bricks generally include first-level high alumina bricks, second-level high alumina bricks, third-level high alumina bricks, mullite bricks, etc. The alumina content of each type of high alumina brick is different. Therefore, the parts where the temperature of the hot air stove is distributed are used in different parts of the hot air stove. Due to its high aluminum content, the material has good fire resistance, high-temperature resistance, and corrosion resistance. These characteristics make high alumina bricks one of the ideal choices for hot blast stoves.

When selecting high-alumina bricks for hot blast stoves, the high-temperature creep properties of refractory bricks should be taken into consideration to ensure production safety in long-term work. Therefore, we need to select each part in the early stage and choose different varieties and brands of refractory bricks. The selection of refractory materials used in various parts of the hot blast stove is based on the temperature of the heating surface where it is located, and it can work stably for a long time under load-bearing conditions.

Blast furnace hot blast stoves in my country are generally internal combustion type, and their linings and checker bricks are generally constructed of high alumina bricks and clay bricks. The high-temperature parts of external-fired hot blast stoves are generally built with silica bricks. For medium and low-temperature parts, high alumina bricks and clay bricks are used in turn.

How much does a ton of ordinary high-alumina refractory bricks cost for hot blast stoves?

There are many types of refractory bricks used in hot blast stoves, and high alumina refractory bricks are one of them. However, high alumina refractory bricks for hot blast furnaces are divided into ordinary high alumina bricks and low creep high alumina bricks. How much does a ton of ordinary high-alumina refractory bricks for hot blast stoves cost? The price of high alumina bricks is generally a concern of users. RS Cheap Fire Bricks Factory will analyze it based on the actual working conditions.

Before understanding the price of ordinary high alumina refractory bricks, let us briefly understand the basic information of high alumina refractory bricks. Ordinary high-alumina refractory bricks for hot blast stoves use high-alumina bauxite as the main refractory raw material. Powder, additives, and binders are added, and the formula is prepared in proportion, mixed, and high-pressure molded before being fired in the kiln. The fired-high alumina bricks can be used in industrial kiln environments around 1500°C. It has the advantages of stable thermal shock resistance, high compressive strength, and strong corrosion resistance. Ordinary high alumina refractory bricks for hot blast stoves are divided into three grades according to different aluminum contents: 65 high alumina bricks, 55 high alumina bricks, and 48 high alumina bricks.

Which parts of the hot blast furnace are generally used for ordinary high alumina refractory bricks?

Ordinary high-alumina refractory bricks are used as linings on the top and walls of hot blast furnaces. Special attention should be paid to the thermal shock stability of high-alumina bricks used in furnace tops to prevent the bricks from peeling off or breaking due to sudden temperature changes. The furnace lining is affected by the rapid temperature changes during the heat exchange process, the chemical erosion of dust brought in by the blast furnace gas, the mechanical load, the scouring effect of the combustion gas, etc., which all impact the furnace lining refractory materials. Therefore, refractory bricks with good stability and corrosion resistance are needed.

I learned about the production of ordinary high alumina bricks and their use parts and physical and chemical indicators in hot blast stoves. I also have a certain understanding of the configuration of high alumina bricks for hot blast stoves. Through this information, we also have a certain understanding of the price of high alumina bricks. So, how much does a ton of ordinary high-alumina refractory bricks for hot blast stoves cost? Comparing the actual situation with the market price of high alumina bricks, the price is about 2,800 yuan to 3,500 yuan. Why is there a price range? This is what confuses many people. From the above information, we can understand that there are three brands of high-alumina refractory bricks for hot blast furnaces. Different brands of high-alumina bricks have different aluminum contents, and their properties are different, which is also a factor leading to different prices.