Magnesia-carbon bricks are made of magnesia, dead-burned magnesia, fused magnesia, high-purity magnesia, high-quality graphite, and bauxite additives. The price and performance of magnesia carbon bricks have a lot to do with the graphite content in the bricks. As the graphite content increases, the strength of the brick decreases, the thermal expansion rate decreases, and the residual expansion rate increases. Therefore, the graphite content in the brick should be controlled at about 20%. RS Cheap Fire Bricks Factory can supply high-quality premium Magnesia Carbon Bricks for Ladles. To buy magnesia carbon bricks, please choose a high-quality magnesia carbon brick manufacturer.

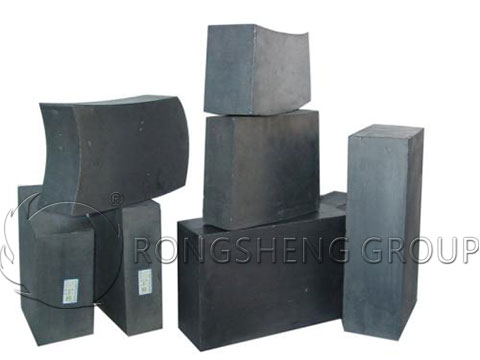

Magnesia Carbon Brick for Ladle Slag Line

Magnesia-carbon bricks have low wettability to slag, excellent spalling resistance, and corrosion resistance, and are suitable for the slag line of the ladle, especially for the occasion of continuous pouring of multiple furnaces. In order to meet the needs of producing clean steel, the application site of magnesia carbon bricks has expanded from the slag line to the side wall during refining in the ladle.

When building magnesia-carbon bricks on ladles, care should be taken not to mix them with bricks with high SiO2 content. Otherwise, the local melting loss of magnesia carbon bricks will be increased. Magnesia-carbon bricks are mainly used in the furnace lining and taphole of steelmaking oxidation conversion furnaces, and the hot spots of high-power electric furnace walls. As well as the lining of the refining furnace outside the furnace, the slag line of the steel ladle, etc.

During the smelting process, the conditions of use and damage of each part of the converter are different. In order to achieve balanced corrosion, the grade and quality of the selected magnesia carbon bricks are also different for each part of the converter under different operating conditions.

The temperature of the furnace mouth and the furnace cap changes drastically, and the slag corrosion is more serious. Magnesia carbon bricks with good thermal shock resistance and strong slag resistance should be selected. In addition to being damaged by blowing on both sides of the trunnion, there is no protective slag layer cover on the surface, which is not easy to repair, and the carbon in the brick is easy to oxidize. High-quality magnesia-carbon bricks with excellent slag resistance and good oxidation resistance should be built. The slag line part is in long-term contact with molten slag and is seriously corroded by slag. It is necessary to build magnesia carbon bricks with excellent slag resistance. The splashing action of slag and molten steel during oxygen blowing on the charging side is likely to cause chemical erosion, abrasion, erosion, and direct impact and erosion of scrap steel and molten iron on the charging side. Magnesia carbon bricks with strong slag resistance, high-temperature strength, and good thermal shock resistance should be selected. The hearth and furnace bottom are less eroded than other parts, and ordinary magnesia-carbon bricks can be used. When the top-bottom composite blowing technology is used, especially when CO2, O2, and other gases are blown at the bottom, the damage is more serious. High-grade magnesia-carbon bricks with good oxidation resistance, good thermal shock resistance, high-temperature strength, and strong slag resistance should be selected. According to the use of different parts of the converter, the selection of converter magnesia carbon bricks with corresponding performance is an effective way to improve the technical and economic indicators of the converter.

Magnesia Carbon Bricks Resistant to Slag Erosion

The raw material for preparing magnesia-carbon bricks is fused magnesia with a MgO content of 98%. Magnesia carbon bricks are characterized by their low porosity, resistance to slag erosion, thermal shock resistance, and high-temperature strength. They are mainly used in basic oxygen furnaces, mid-grade magnesia, ladle slag lines, and electric arc furnace hot spots. Magnesia carbon brick is a high-quality refractory material. Their main components are magnesia and carbon, wherein the magnesia content is 60-90%, and the carbon content is 10-40%. This material is made of high-purity magnesium oxide particles, carbon materials, tar, pitch, or resin and baked at high temperatures. These magnesia refractory bricks have the characteristics of slag corrosion resistance, thermal shock resistance, thermal conductivity, and so on.

Magnesia carbon brick is an unburned carbonaceous composite refractory material, which is made of magnesia with a high melting point (2800°C) basic oxide and a high melting point carbon material. The material is resistant to attack by slag, and various non-oxide additives and carbon binders are added.

The magnesia contained in magnesia carbon bricks depends on the material used. Common magnesia carbon bricks mainly include 72% magnesia, 74% magnesia, 76% magnesia, 80% magnesia, 82% magnesia, and 85% magnesia. Ladle magnesia-carbon bricks, The main raw materials used in the production of magnesia-carbon bricks are fused magnesia, graphite, metal aluminum powder, metal silicon powder, and liquid phenolic resin, which are stirred by a sand mixer and pressed by a press. Magnesia-carbon bricks are used in refining ladle slag lines, and magnesia-carbon bricks are also used in AC electric arc furnaces, DC electric arc furnaces, converters, and other furnace linings.

Electric furnace magnesia carbon brick steelmaking is equipment that uses the arc generated between graphite electrodes as the heat source for steelmaking. It is divided into DC electric furnace and AC electric furnace, among which AC electric furnace accounts for the majority. In this work, according to the damage mechanism of the electric furnace, the magnesia-carbon bricks suitable for the electric furnace were developed and produced.

To learn more about the price information of magnesia carbon bricks, please contact us. We can customize magnesia carbon bricks, ladle refractory lining materials, etc. according to your working conditions.